The Newsroom

Latest news and insights from American Eagle Paper Mills

Built in 1881, the mill operated continuously for 120 years until its former own unexpectedly ceased operations. A group of mill manger partnered with local inventors to save the mill and establish American Eagle Paper Mills.

AEPM is the only manufacturer of 100% recycled printing, witting, color, and specialty papers in the US, and the only integrated producer in North America. The mill's 200 skilled craftsmen produce over 200 tons of premium paper per day.

AEPM had become the leader in sustainable paper, investing more than $44MM over the past two decades in paper recycling equipment, eliminating 8.45MM tons of CO2 emissions and saving 39MM trees. They are currently raising a 140-year-old power plant to build a recycling operation to recombine the plastics removed from their post-consumer feedstocks and residual fiber to produce a new polymer resin for injection molders.

Read More

Read More

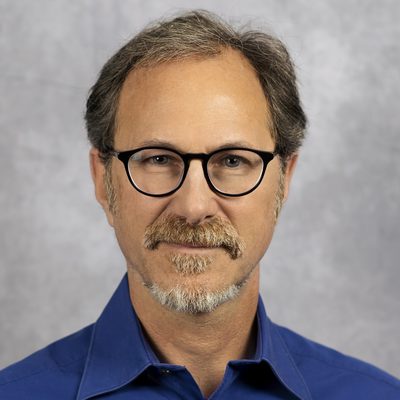

Phil leads his family business group of 1000+ associates across engineering, manufacturing and installation of sign and fascia systems, recycled paper production, car dealerships, real estate, and a host of venture investments.

Phil leads his family business group of 1000+ associates across engineering, manufacturing and installation of sign and fascia systems, recycled paper production, car dealerships, real estate, and a host of venture investments. Phil grew Blair Image Elements from a small sign manufacturer to a full-service image provider for 50 of the world’s largest companies. During his tenure at American Eagle Paper Mills, the company shifted toward 100% recycled and specialty papers to achieve new highs. Prior to joining Blair in 1992, Phil led a risk management team for Sony Music and was a consultant for Senn-Delaney. He has an MBA and a BS in Operations Research & Industrial Engineering from Cornell University.

Phil is active in the community, including leadership roles at Mount Aloysius College, PA Early Learning Commission, PSU Altoona, Operation Our Town, YPO, and the Blair Chamber. He resides in Altoona, PA with his wife Colleen and has three children, Max, Claudia and Felicia.

Read More

Read More

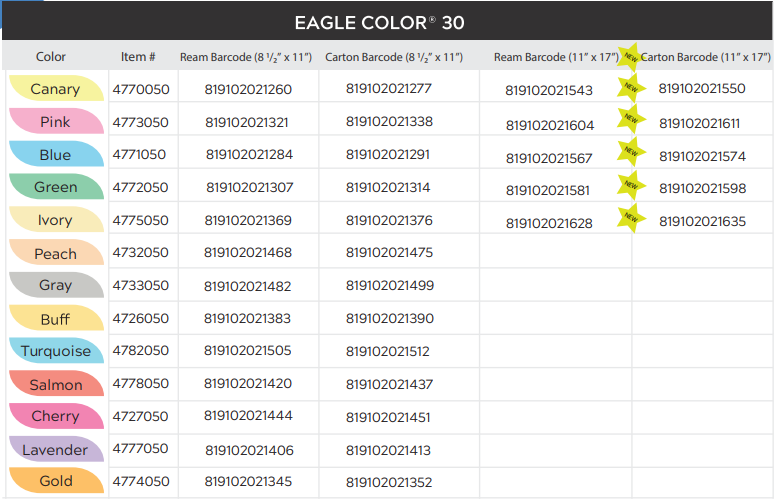

American Eagle Paper Mills® is pleased to announce that we are adding 11 x 17 to our 20# Eagle Color 30 cut size portfolio.

American Eagle Paper Mills® is pleased to announce that we are adding 11 x 17 to our 20# Eagle Color 30 cut size portfolio. Our five select colors include canary, green, blue, pink, and ivory and are available for immediate shipment. As with all our products these can assort with other Eagle grades for truckload delivery. The minimum order quantity of any Eagle cut size item remains one pallet.

The Sell Sheet is available on demand on our website, www.aepaper.com under the “Our Paper” tab in both a printable and exportable pdf file.

For your convenience, we have included a listing of the new item numbers along with a graphic representation of the carton label which graphically distinguishes our 11 x 17 packaging with a corresponding color border around the perimeter of the label.

As always Eagle Color® 30 continues to build on our portfolio of recycled alternatives: 30% recycled, FSC certified, and Elemental Chlorine Free.

If you have any questions or would like additional information, please do not hesitate to contact us at csr@aepaper.com, (814) 684-1610 (option 1) or contact your local sales representative.

Thank you for your continued support of American Eagle paper Mills®.

Read More

Read More

American Eagle Paper Mills® is pleased to announce that we are refreshing our color cut size line. On a rolling basis starting in late August, we will be transitioning from Premium Color 30 to our new Eagle Color® 30. This change aligns our Eagle Color® 30 with our Eagle Office® portfolio of products.

To Our Valued Customers:

American Eagle Paper Mills® is pleased to announce that we are refreshing our color cut size line. On a rolling basis starting in late August, we will be transitioning from Premium Color 30 to our new Eagle Color® 30. This change aligns our Eagle Color® 30 with our Eagle Office® portfolio of products.

The changes to our new Eagle Color® 30 product line include:

- Enhanced and updated packaging

- Ream and carton UPC Codes

- FSC Certification

Attached is our new sales flyer providing all the basic information for our 13 Eagle Color® 30 products along with a sample jpg photo revealing our vibrant new carton packaging.

We, at American Eagle Paper Mills® are excited about merging our Eagle Color® 30 line with our existing Eagle Office® portfolio.

Should you have any questions or concerns, please don’t hesitate to contact our Customer Service team at csr@aepaper.com.

Regards,

Greg

Greg Bowen

VP Sales & Marketing

American Eagle Paper Mills®

Read More

Read More

Tyrone, PA - June 2, 2021 - American Eagle Paper Mills announced today Allan Bobb, Machine Room Superintendent, and Colin Symons, Furnish Prep Manager, have become the first employees invited to the ownership team since the Mill reopened in 2003.

“This a cause for celebration amidst challenging times in our industry and our community. Buying into the Mill underscores the significant commitment Allan and Colin have made to American Eagle and to their fellow employees. They bring dedication and talent to the Mill every day. They believe in the Mill’s future and are an important part of its success,” said Scott Igoe, President and partner.

Board member Philip Devorris agreed. “I couldn’t be happier than having Allan and Colin join the ownership team, a group that includes long-time employee-owners, Igoe, Clark Adelman and Bill Naugle. As an outside owner, along with my partners Harry Sickler and Todd Lewis, we recognize Allan and Colin as key leaders in the Mill’s future.”

Bobb joined the Mill in 2008 as a Chemical Engineer. He gained broader experience in technical and managerial positions, most recently as Furnish Prep Manager, before moving to the Machine Room as Machine Room Superintendent. “The technical expertise and adaptability our people bring in expanding our product line, all while utilizing recycled feedstock, is really what sets American Eagle apart in the paper industry. I've always taken pride in being a part of the team that brings a new product from the development phase to that first shipment,” Bobb explained.

Symons began interning at the Mill in 2015 while studying Electro-Mechanical Engineering Technology at Penn State Altoona and was promoted soon after he began working full time. “Our Furnish Prep operations involve a fair amount of puzzle-solving. We produce paper to very exact specifications from a wide range of reclaimed fiber sources. I am fortunate to be a part of such a talented team of paper makers; their ingenuity and can-do spirit are the foundation of our business. They make the job interesting and enjoyable,” Symons shared.

When asked about the Mill’s future, Adelman, who manages the client team along with his CFO responsibilities, emphasized, “Our Mill is uniquely positioned as the nation’s only 100% recycled sheet provider. As the world looks to increase sustainability and reduce our environmental footprint, this is a growth area in an otherwise shrinking market. It is exciting to see major new clients support our rapid expansion into recycled specialty grades, strengthening our business for the future. I know the Mill is in good hands with Allan and Colin joining our ownership team.”

About American Eagle Paper Mills

American Eagle Paper Mills is the leading US producer of recycled uncoated freesheet papers, including office, printing, and converting grades. Despite being one of the oldest mills in the US, American Eagle’s continuous innovation and infrastructure investment has improved efficiency while earning the Mill numerous environmental awards for reducing water usage by 83% and greenhouse gas emissions by 68%. Located in Tyrone, PA, the Mill was founded in 1881. It was shuttered briefly before being restarted in 2003 by a team of long-term Mill employees backed by local investors. The Mill employs over 200 proud Pennsylvania papermakers, transforming 300 tons of waste each day into premium recycled papers. To learn more about American Eagle Paper Mills and our sustainability story, please visit aepaper.com.

Read More

Read More

Scott joined the Tyrone Mill in 1987 as a production engineer and assumed roles of increasing responsibility in supervision until the mill shutdown in 2001.

He gained broader experience across four years in production positions at two other mills, before returning as an equity partner in 2003 to re-open the Mill.

Scott led the effort to restart the idled paper mill, providing direction in the areas of hiring, operator and supervisor training, paper production, fiber and furnish prep, quality, product development, paper machine scheduling, and order acknowledgement. In 2007, Scott was promoted to Executive Vice President of Operations, assuming broader responsibility for all mill production areas, including paper production, converting, engineering and maintenance.

Scott assumed the role of President in 2020, adding finance and administrative responsibilities to his historic production and technical roles. Scott graduated from the University of Maine in 1986 with a BS in Chemical Engineering.

Read More

Read More

We are pleased to announce that the Eagle Armor® product line at American Eagle Paper Mills® continues to grow and expand as we take this family of grades to market.

We are pleased to announce the following updates:

- Eagle Armor® Office 20# 8 ½ x 11 is now stocked on our floor for immediate delivery. The minimum order quantity is one pallet.

- Eagle Armor® Envelope 24# is currently being stocked. These rolls can be used to slit and rewind quick turn roll or sheet orders. The minimum order quantity is 10,000lbs for sheets and 5,000 lbs for rolls.

- Eagle Armor® Offset 50# and 80# is now available. These rolls can be used to slit and rewind quick turn roll or sheet orders. The minimum order quantity is 10,000lbs for sheets and 5,000 lbs for rolls.

- As we continue to expand the Eagle Armor® brand we are encouraged by the initial interest and demand. Please keep the above initial guidelines in mind when thinking about the Eagle Armor® line of products. Additional stocking items may be added as a result of changes in demand. Stock is available on a first come first serve basis. Make-to-order items typically require a 2-4 week lead time.

As promoted, Eagle Armor® can be applied to any of the products we manufacture using the Silver Ion technology developed by Biomaster®. The Eagle Armor® additive does not alter the look, feel, shade or specifications of the grade. Eagle Armor® provides antimicrobial protection against unwanted microorganisms that could damage the paper without affecting product performance.

For additional information about Eagle Armor® and a complete list of our products, please visit our website at www.aepaper.com or call Jay Lyons directly (339) 788-1343 or a member of our Customer Service team at (814) 684-6146.

Read More

Read More

American Eagle Paper Mills announced Friday the appointment of Scott Igoe as company President. “This is a cause for celebration amidst challenging times in the industry, our community, and the world.

Scott has dedicated nearly his entire career to American Eagle and its employees. His commitment to excellence and sound judgment have been a driving force behind its success,” said board member Philip Devorris.

A chemical engineer, Igoe joined the Mill in 1987 as an Operations Engineer under Westvaco ownership. He gained broader experience over four years in technical and managerial positions at mills in Maine and Virginia, before returning as an equity partner in 2003 to help reopen the American Eagle paper mill in Tyrone.

Igoe led the effort to restart the idled paper mill, providing direction in the areas of hiring, operator and supervisor training, paper production, fiber and furnish prep, product development and quality, scheduling, and order acknowledgment. In 2007, Igoe was promoted to Executive Vice President of Operations, assuming broader responsibility for all Mill production areas.

Igoe succeeds Devorris in the position. Devorris, who took over as Interim President in December 2018, will remain in his role on the Mill’s Board. Despite a very challenging market over the past few years, the Mill just posted its best quarter since 2016, behind new product introductions such as a wide range of colors and state-of-the-art digital printing grades, all made of premium recycled paper. “This business has tremendous potential, and I’m honored to lead this great team of people, as we continue to set new standards for sustainability in our industry,” said Igoe.

Devorris offered: “I have greatly enjoyed the opportunity to work more closely with AEPM’s many exceptional employees the past couple of years. I am very pleased with the Mill’s steady progress, and with Scott at the helm, I’m tremendously optimistic about our future.”

Read More

Read More

Pennsylvania Governor Tom Wolf announced today that American Eagle Paper Mills will receive a 2018 Governor's Award for Environmental Excellence for its Project Phoenix.

The Pennsylvania Department of Environmental Protection (DEP) chose 23 organizations from more than 60 applications. Applicants were evaluated for their degree of environmental protection, innovation, partnership efforts, economic impact, consideration of climate change and sustainability with results achieved.

“Just as important as Pennsylvania’s abundant natural resources are the Pennsylvanians who invest their time, labor, and ingenuity to protect them,” said Governor Tom Wolf. “Their dedication results in public health and safety, environmental, economic, and recreation benefits across the commonwealth.”

American Eagle Paper Mills commissioned Project Phoenix to increase energy efficiency and reduce water usage at their Tyrone, Pennsylvania mill – one of the oldest working paper mills in the United States. Infrastructure updates; including a transition to natural gas from coal, resulted in an 83 percent reduction in daily river and watershed water withdrawal while reducing greenhouse gas emissions by 68%.

“This is the third sustainability award honoring American Eagle Paper Mills over the past year. We are very proud to accept this recognition for our sustainability efforts" stated CEO Mike Grimm, noting that the mill was also recently honored by AF&PA and the Pennsylvania Resources Council. "Our $8 million dollar investment in Project Phoenix not only benefited the mill with efficiency savings; it also benefited the Pennsylvania community in which our workers live and raise their families. The air is cleaner, the natural watershed improved, and the paper mill is more efficient and better positioned to sustain good paying jobs in Tyrone, PA.”

The Pennsylvania Environmental Council and DEP is hosting a dinner to honor the award winners on April 24th at the Harrisburg Hilton. More information about the Governor's Awards for Environmental Excellence is available through the DEP release or website

Read More

Read More

American Eagle Paper Mills has announced an important addition to the Eagle family of recycled printing papers, Eagle Inkjet™ 100. Eagle Inkjet 100 is engineered to deliver exceptional print performance across multiple high speed inkjet platforms.

Produced from 100% post-consumer recycled fiber, Eagle Inkjet 100 offers a high quality, sustainable paper option for consumers and corporations looking to minimize their environmental footprint. It is an ideal and environmentally conscious choice for direct mail, transpromotional marketing and transactional printing.

Eagle Inkjet 100 has an extra smooth surface that yields exceptionally sharp inkjet image reproduction. It is bright and clean; virtually indistinguishable from a virgin fiber paper, and is priced to compete with virgin high speed inkjet papers. Produced from 100% post-consumer recycled fiber, Eagle Inkjet 100 is acid free for archival purposes and is process and elemental chlorine free. It is FSC certified and is the only 100% recycled high speed inkjet paper made in the USA.

Eagle Inkjet 100 is available in 60#, 70#, 80# and 7pt reply card rolls (24#, 28#, and 32#) and is supported with a roll stocking program at the mill in Tyrone, PA.

CEO Mike Grimm says, “We are proud be expanding our recycled paper portfolio into evolving and growing print segments like high speed inkjet. Our recycled products are uniquely positioned in these markets to help meet the sustainability initiatives being embraced by consumers and corporations around the world.”

Read More

Read More

The American Forest & Paper Association (AF&PA) recognized American Eagle Paper Mills with a 2017 AF&PA Leadership in Sustainability Award for Water for their Project Phoenix. The award was presented at AF&PA’s annual meeting on Friday, Nov. 3 in Greensboro, Georgia.

“American Eagle’s Project Phoenix proves that intentional focus on increased efficiency benefits company operations – environmentally, socially and economically,” said AF&PA President and CEO Donna Harman.

American Eagle Paper Mills commissioned Project Phoenix to increase efficiency and reduce water use at their Tyrone, Pennsylvania, mill – one of the oldest working paper mills in the United States. Infrastructure updates resulted in an 83 percent reduction in total daily river and watershed water withdrawal; a 91 percent reduction in daily water consumption; and an 18.1 percent reduction in process water effluent per ton of paper produced.

“Thank you to AF&PA for recognizing Project Phoenix,” said American Eagle President and CEO Michael Grimm. “We are proud of the positive effects our efforts have had on our operations and our Tyrone community.”

Designed to recognize exemplary sustainability programs and initiatives in the paper and wood products manufacturing industry, AF&PA’s annual sustainability awards are given based on the merit of entries received across multiple categories.

Projects that support progress toward the Better Practices, Better Planet 2020 sustainability goals qualify for recognition in the “Leadership” category, which has five subcategories that correspond to the goals: Paper Recovery for Recycling, Energy Efficiency/Greenhouse Gas Reduction, Sustainable Forest Management, Safety, and Water. The “Innovation in Sustainability” award is reserved for projects that merit recognition for their contribution to sustainable business practices, not one of the goals specifically.

AF&PA releases its sustainability report every other year. The 2016 Sustainability Report showed that the U.S. pulp, paper, packaging, tissue and wood products manufacturing industry has made significant, measurable progress toward achieving its Better Practices, Better Planet 2020 sustainability goals.

About AF&PA

The American Forest & Paper Association (AF&PA) serves to advance a sustainable U.S. pulp, paper, packaging, tissue and wood products manufacturing industry through fact-based public policy and marketplace advocacy. AF&PA member companies make products essential for everyday life from renewable and recyclable resources and are committed to continuous improvement through the industry’s sustainability initiative - Better Practices, Better Planet 2020. The forest products industry accounts for approximately four percent of the total U.S. manufacturing GDP, manufactures over $200 billion in products annually, and employs approximately 900,000 men and women. The industry meets a payroll of approximately $50 billion annually and is among the top 10 manufacturing sector employers in 45 states. Visit AF&PA online at www.afandpa.org or follow us on Twitter @ForestandPaper.

About American Eagle Paper Mills

American Eagle Paper Mills is the leading US producer of recycled uncoated freesheet papers, including office, printing and converting grades. Located in Tyrone PA, the mill was restarted in 2003 by a group of local investors, having been shuttered by MeadWestvaco in 2001. The mill employs approximately 240 proud Pennsylvania papermakers, who transform 300 tons of waste paper each day into premium recycled paper. To learn more about American Eagle Paper Mills and our sustainability story please visit www.aepaper.com.

Read More

Read More

American Eagle Paper Mills today announced that it joined the SmartWay Transport Partnership, an innovative collaboration between U.S. Environmental Protection Agency (EPA) and industry that provides a framework to assess the environmental and energy efficiency of goods movement supply chains.

American Eagle Paper Mills will contribute to the Partnership’s savings of 170.3 million barrels of oil, $24.9 billion in fuel costs, 72.8 MMT of carbon dioxide (CO2), 1,458,000 tons of nitrogen oxides, and 59,000 tons of particulate matter. This is equivalent to eliminating annual energy use in over 6 million homes. Carbon dioxide is the most common greenhouse gas, and nitrogen oxide is an air pollutant that contributes to smog. By joining SmartWay Transport Partnership, American Eagle Paper Mills demonstrates its strong environmental leadership and corporate responsibility.

“As an industry leader in sustainable papermaking, American Eagle Paper Mills continually looks for ways to manufacture, package and deliver our recycled papers with minimal impact on our shared natural resources. Our partnership with Smartway is a tangible demonstration of our effort to deliver our papers in the most environmentally efficient way possible, minimizing our overall environmental footprint,” said Mike Grimm, President and CEO of American Eagle Paper Mills.

Developed jointly in early 2003 by EPA and Charter Partners represented by industry stakeholders, environmental groups, American Trucking Associations, and Business for Social Responsibility, this innovative program was launched in 2004. Partners rely upon SmartWay tools and approaches to track and reduce emissions and fuel use from goods movement. The Partnership currently has over 3,000 Partners including shipper, logistics companies, truck, rail, barge, and multimodal carriers.

American Eagle Paper Mills is the leading US producer of recycled uncoated freesheet papers, including office, printing and converting grades. Located in Tyrone PA, the mill was restarted in 2003 by a group of local investors, having been shuttered by MeadWestvaco in 2001. The mill employs approximately 240 proud Pennsylvania papermakers, who transform 300 tons of waste paper each day into premium recycled paper. To learn more about American Eagle Paper Mills and our sustainability story please visit aepaper.com.

Read More

Read More

The press of a button sounded a whistle Thursday morning outside American Eagle Paper Mills, symbolizing the installation of new technology and a move toward the future.

Mill officials opened their new warehouse and customer service center to the public including local politicians and business leaders to highlight a new natural gas boiler that replaced aging equipment and improved operations.

"Shortly after I took the reins in 2013, I realized we had a big problem to deal with," said Mike Grimm, the mills' president and CEO. "It was one of those problems that keep you up at night. The type of problem that just doesn't go away when the market improves."

The problem, he said, was that the mills' power infrastructure was installed in 1957 and had been operating almost continuously since then. The critical piece of equipment a coalstoker fire boiler was nearing the end of its life, and there was "limited capital to solve such a problem," Grimm said. Still, through due diligence and a competent leadership team, Grimm said he found that a solution was not out of reach.

"We found something in the end that really wasn't that complicated," he said. "The key to that solution was efficiency." This summer, the new boiler a $3.5 million update was completely installed, Grimm said. "I've been a project guy my whole career, and I can tell you this was the best executed project I've ever worked on," Grimm said. "The interesting part is this was engineered and built up mostly by our own employees." In addition to keeping the mill running and employees employed, the papermanufacturing operation has been made more environmentally responsible as a result of recent advancements, Grimm said. Greenhouse gas emission have been reduced 70 percent annually, and the amount of water withdrawn from local water sources also has been reduced drastically.

That reduction, Grimm said, is about 11,532,000 gallons per day or 4,209,180,000 gallons annually. "We've made a profound environmental impact as the result of this project. ... This is a remarkable success story of how a small company can make a big difference," he said. Present innovations were an obvious focal point Thursday, but the past was not absent from the presentation.

Displays set up in the warehouse chronicled the business' 136 years. And Grimm took time during his speech to reflect, especially on hard times, including a span from 200103 when the mill closed. However, Grimm also talked about the group of leaders and investors that brought the business back into production.

"This is a story of incredible individuals from a local community that came together to set this course. The leadership and persistence of a handful of people is why we're here today," he said. Among those mentioned were former AltoonaBlair County Development Corp. President and CEO Marty Marasco, former state Sen. Robert Jubelirer and former state Secretary of Agriculture Samuel Hayes Jr. each of them spoke at the ceremony. "I've had the opportunity to work with some great people," Marasco said. "I'm most proud to have had the opportunity to work with this group of great people ... but the real heroes are the investment group and the management group." Jubelirer also commented on those leaders' ability bring the business back to success.

"The future of Tyrone literally depended on whether this mill would open again," he said. "What you can accomplish if you work together my goodness gracious, you can get a lot done." And lastly, Hayes praised American Eagle Paper Mills' past and present employees, who he called "hardworking people that turned out a good product." Hayes' comments took him back to his youth. "Everyday in those schoolboy years, I was in class with the sons and daughters of the paper makers. And they were proud of their fathers and their mothers who worked at this mill," he said. "Make no mistake, I made note of the fact that my classmates were proud to be from a papermaking family." Eventually, Grimm turned his speech to the company's future, which he said looks advantageous with the mills' continued focus on modern methods, such as producing recycled paper.

"The recycled market is actually growing; it's not shrinking," Grimm said. "We are succeeding in innovating while being a small U.S. manufacturer." At the event's conclusion, several officials gathered to press a button that sounded a whistle, which had been silent since renovations began. The whistleblowing took the place of the typical ribbon cutting, Grim said. "The paper whistle means many things to many people. ... After today, the whistle will blow again," he said.

Mirror Staff Writer Sean Sauro is at 9467535.

Read More

Read More

An ongoing 45% demand decline on uncoated freesheet (UFS) paper in North America since 2000 has not deterred American Eagle Paper Mills.

The 90,000 tons/yr mill in central Pennsylvania with a long, colorful history remains fixated and growing in UFS.

In the last two years, the company spent $15 million on a critical coal to natural gas boiler project that significantly reduces the mill's production cost, opened a new warehouse, and started up a second cutsize sheeter. Further, company CEO Mike Grimm, who started at American Eagle Paper in early 2013, sees continuing interest and growth potential in 100% recycled-content office/copy paper, which is an American Eagle staple. In 2015, for example, the city of New York started using 100% recycled-content office paper at its government offices.

Next week, American Eagle Paper celebrates the capital spending advancements. More than 100 guests are expected, including bankers and politicians. The mill in Tyrone, first erected in 1880, was shut in the fall of 2001 by Westvaco – while Westvaco and Mead combined in a $3 billion merger that was completed in early 2002.

2003 restart. Former mill personnel manager John Ferner led an investor group Team Ten LLC that acquired the Tyrone assets in July 2003 and the mill, which had made both uncoated and coated printing and writing papers, restarted as an UFSonly operation in November 2003.

The same challenge as in 2003 remains today, according Grimm. American Eagle Paper's share of the North American UFS market is 1%.

"The challenge we all face is a declining market," he said. "For us, we must sell in the right places … with a flexible operation that can do a number of different things – all with the same overhead structure."

"I didn't grow up in this industry," said Grimm. "What's the future going to look like in terms of the supply of paper? Is it going to be coming out of a few large systems only or also localized systems that are scaled. My gut tells me that mill operations that can produce products that serve several segments of the market while being very efficient will succeed."

Since 2013, along with the demand decline from mobile device use that replaces print on paper, five US UFS producers – –including the largest four – –shut down almost 1.5 million tons/yr of capacity. That 1.5 million represents 17% of today's North American demand.

Grimm said a tour of the Tyrone mill next week will start at the legacy 1957 boiler house that is eight stories tall. The newly-installed Babcock and Wilcox natural gas package boiler is much smaller, emblematic of the mill's changes. The reduced energy footprint of the mill led to the shuttering of the 60-year-old power generation equipment as well.

The mill negotiated a five-year electricity contract at a cost that is lower than what it would cost American Eagle to produce the power on-site at the mill with existing equipment, Grimm said.

"This is a solid five-year plan allowing us to cut cost and focus our capital on our business vs overleveraging to make power. We can circle back in the future and reinvest in co-gen at a later time," he said.

The old equipment shut July 10 and the new boiler starting running on July 16. No longer is the mill a 70,000 tons/yr coal consumer paying to landfill 10,000 tons/yr of coal ash. Its emissions declined by 70%. Its water usage was cut by 82% or a staggering 11.5 million gallons per day.

New grades. The mill's two paper machines are non-pulp integrated, running primarily on pulp from recovered paper including hard white envelope cuttings. The 152-in-wide trim machine No. 3, a Pusey and Jones unit installed in 1950, and 84-in PM 4, also a Pusey and Jones unit but installed in 1910, make office/copy, offset, envelope, and reply card papers. This week, Grimm added that the company is shipping some new grades of paper never made before on the mill's machines. "We're not going anywhere. We are continuing to grow and adapt continuously. The small guy can be successful," he said.

Read More

Read More

The American Eagle Paper Mill is a significant piece of Tyrone history. Since the paper mill opened in 1880, many in Tyrone have found their livelihoods in the mill. Both the paper mill and the railroad had a great economic impact on the town and its residents.

We began looking back at the paper mill a few weeks ago in order to honor the past, while celebrating the present and looking towards the bright future for the mill and its people. In this photo recently discovered in a box of historic memorabilia at the mill, names were handwritten on the back. Some of the writing was a bit difficult to read, so we apologize that some of the names may be misspelled.

The names listed are Walter Chronister, W. C. Owens, Bill Glenny, Oliver Ormsby, Karl Getz, Bennie Parks, Roy Bohns, S. Gripp, Ed Skeys, Chas Davidson, Wid Maschke, Mable Snyder, Elizabeth Louder, Peg Woomer, Lois Beam, Betty Merritts, Eleanor Skeys, Bell McNelius.

Maybe one of them is a relative of yours. If you have any knowledge of any of the people listed, we would enjoy hearing your story as we take this step back in time. From those who served to blow the whistle, to those whose jobs were counting papers (also known as "counter girls"), to those who ran the machinery, all might have stories to tell.

The American Eagle Paper Mill is also interested in finding those who are among the oldest living employees who had worked at the mill. If you have any historical information to share regarding the paper mill, please contact the Herald at (814) 684-4000, stop in our office along Pennsylvania Avenue, or send e-mail to the following address jwhite@thedailyherald.net

Mirror Staff Writer Sean Sauro is at 9467535.

Read More

Read More